5 Best Cheap Plasma Cutters That You Can Buy in 2023

Crafting things at home isn’t just about cutting paper, making leaflets or woodcraft, since sometimes you’ll have to work with much more heavy-duty materials, especially if the thing you’re working on is supposedly something durable.

For example, although it may sound complicated at first, welding is also something that the average user can do by themselves, although having a plasma cutter can indeed come in handy.

Unfortunately, for all of their usefulness, plasma cutters tend to be on the expensive side, so if you’re on a tight budget, making sure that you benefit from the best cost-performance ratio suddenly becomes a priority, and that’s when you need a budget-friendly plasma cutter.

However, the Internet is vast, and even a product that may not seem so sought like a plasma cutter can still be found under hundreds of labels and thousands of model names, and this makes choosing the right one for you rather difficult.

Because of that, we’ve decided to do the grunt work for you and compiled a list of the best plasma cutters on the market today that can be deemed as being very budget-friendly, while still maintaining high-performance standards to get the job done right.

Table of Contents

How Much Does a Plasma Cutter Cost?

The main reason you’re reading this article is probably that you’re looking for a plasma cutter and the price tag is your main criteria.

Well, a quick Internet browse will show you that a plasma cutter can cost anywhere between $250 and $1500, but of course, the prices can go even higher, but that’s purely the case with industrial cutters.

Presuming that you are a regular person that just wants to do some welding and metal cutting around the house, we advise that you go for plasma cutters that are durable, versatile, and have low maintenance and consumable costs.

Sure enough, you can opt for a plasma cutter with a lot of cutting power that is pricier, but if you’re only ever going to use it at its full potential just once (if ever), then that would be financial overkill.

That being the case, the products that we will be showcasing aren’t necessarily the cheapest, but rather the plasma cutters with the best price/performance ratio.

Where Can I Buy an Affordable Plasma Cutter?

Whenever you’re considering buying a new product, plasma cutter or otherwise, the first place you should always look for is the manufacturer’s official website. Not only do they have the best prices (third party sellers will usually add a fee of their own), but their customer support is sometimes quicker to respond.

However, if you’re interested in the real-life specs of a machine, there’s no better place to buy a machine (especially a costly one like a plasma cutter) than Amazon.

Not only do you get to see the honest reviews of potentially thousands of users, but Amazon also features the occasional sales that can sometimes be bigger than on the manufacturer’s own website.

Besides, Amazon brings the added benefit of having thousands of products that you can compare, whereas a single manufacturer will have just a handful of products that are usually similar in both specs and prices.

The last reason to go ahead and consider buying from Amazon is that you don’t have to wait for too long in order for the product to be shipped to your home.

Sellers that are marked as Prime Sellers benefit from better delivery times and, depending on where you are, you may even get your product within a couple of days.

Expensive vs. Budget Plasma Cutters

This little debate is solely based on how you plan to use the plasma cutter once you buy it. You see, if you’re only ever going to be welding once in a while, a more affordable model will do just as good of a job as a more expensive one.

Sure, they won’t be able to cut just as deep, and the cutting speeds themselves will be lower, but at least the end results will be precise, and the machine will still last for a very long time.

Besides, what’s the use of buying a more powerful and expensive model (even if you have the money to spare) if you never even plan on using it to its full capacity?

However, those of you that do this for a living, such as professional steelworkers will greatly benefit from having a far more powerful plasma cutter, one that has a higher duty cycle ratio and a greater power output.

Sure enough, the initial investment will be high, but considering that the plasma cutter is the tool that brings you the money ( steelwork is incredibly profitable), your initial investment will be returned in no time at all.

However, unlike other types of products where lower prices are usually correlated with reduced quality, things are different with plasma cutters. While they don’t necessarily break easier or do a shoddy job, they just take longer to accomplish the same feats as their more affordable counterparts.

Which Are the 5 Best Budget Plasma Cutters to Buy?

1. Lotos LT5000D Plasma Cutter

Topping off our list is the Lotos LT5000D Plasma Cutter, an extremely compact plasma cutter that is easy to carry around not just because of its reduced size and weight, but also thanks to the built-in handle.

Working with it will be extremely safe because it uses non-hazardous compressed air, and the power output is more than enough to cut even the most common of household metals, such as stainless steel, alloy steel, mild steel, copper, or aluminium.

Speaking of working materials, the Lotos LT5000D Plasma Cutter showcases strong cutting performances with a maximum rated clean-cut thickness of 1/2 inches and a maximum severance thickness of 3/4 inches.

Besides, you don’t have to feel limited by the power sockets that are available nearby, thanks to the plasma cutter’s dual voltage capability which allows the machine to run directly on 220 V 50/60 Hz power, or on a 110 V 50/60 Hz power source.

All in all, The LT5000D is great for both home DIY jobs and as well as some professional projects and you can buy it from Amazon at a special price today!

Specs:

- Duty Cycle:60%

- Size: 15 x 6 x 12 inches

- Weight: 26 lbs

- Input Power:110V/220V 50/60Hz

- Output Current:10-50A

Pros:

- Compact and powerful

- Great price/performance ratio

- Ideal for the average user

Cons:

- Consumables tend to be expensive to replace

2. Super Deal Cut 50 Plasma Cutter

If you’re more interested in the long-term costs of using a plasma cutter than the cost of the initial upfront payment, then we suggest that you look at the Super Deal Cut 50 Plasma Cutter.

Featuring professional-level technology, this plasma cutter offers a more stable performance by combining a high duty cycle percentage with minimal power consumption.

This combination of high temperatures and high plasma draughts in turn means faster cutting speeds, so you’ll not only be making perfect cuts, you’ll do them in record time.

The device itself seems very well made, featuring a body made up almost entirely from iron, so you don’t have to worry about its lifespan being too short.

Another neat thing about this plasma cutter is the way it lets you know how the cuts are going since it comes with a digital LCD display and an easy read front panel air-pressure gauge.

Safety is yet another strong point of this plasma cutter since it comes with multiple protective features, including:

- Overheating protection

- Over-voltage protection

- Under-voltage protection

- Lack of compressed air pressure protection.

Not only that, but the package also comes with a wire and mask, adding yet another protective layer.

Because of its specs, this plasma cutter is good not only for businesses and DIY users but also for professional operators, so if you fall under any of the 3 categories, go ahead and check the Super Deal Cut 50 Plasma Cutter on Amazon.

Specs:

- Duty Cycle:60%

- Size: 18.5 x 11 x 13.5 inches

- Weight: 22 lbs

- Input Power:110/220V 60Hz

- Output Current:20-50A

Pros:

- A wide variety of protective features

- Energy-efficient and very silent

- Fast and efficient cutting

- Solid and reliable build

- Long service life

Cons:

- The instructions manual isn’t very well translated

3. Hypertherm Powermax30 XP

This next plasma cutting machine is all about sheer power, and it is called the Hypertherm Powermax30 XP.

It is a very portable plasma cutter that is also very versatile, being more than capable of handling a wide variety of applications and working with an even wider range of materials.

It comes with a rather unique 2-in-1 design which provides it with enhanced cutting capabilities, allowing it to handle both deep cuts into the thickest of materials, as well as finer cuts in very thin sheets.

It is also very durable, being more resistant to physical damage and extended exposure to heat, and it features rugged torch lead strain reliefs on both ends for even more protection. More so, it works exclusively with air as a gas, so don’t worry about working with any flammable materials.

Using it is also very easy thanks to the one-knob interface design, so controlling temperature and switching between cutting modes will be a breeze.

As for the materials that this plasma cutter can work with, it can deal with any kind of metal, from stainless steel and aluminium to mild steel and even rusted or painted metal.

If this amazing plasma cutter’s cutting prowess has caught your attention, go ahead and check for more details about the specs and the price on the Hypertherm Powermax30 XP’s Amazon page.

Specs:

- Duty Cycle: 20/35%

- Size: 18 x 8 x 11″

- Weight:21.6 lbs

- Input Power:120/240V 50/60Hz

- Output Range: DC:10-30A

Pros:

- Works with all kinds of metal surfaces

- Easy interface

- Very durable build

- Several safety features

- Works only with air as a gas

- Features a 2-in-1 design for both deep and fine cuts

Cons:

- Not as budget-friendly as our other entries

4. AlphaTIG 203XI

The fourth plasma cutter on our list is the AlphaTIG 203XI, and it stands out by deliveringsmartboard technology with an all-new rapid set function.

This feature can adjust the plasma cutter’s power levels by simply choosing the size of your tungsten electrode and the thickness of the material that you are planning to cut, and this works for both AC and DC TIG welding.

Speaking of AC and DC TIG welding, the AlphaTIG 203XI includes customizable AC frequency and AC balance settings that help improve cutting penetration, the life of your tungsten electrode, the quality of the arc cone, and the etching width.

You can use the pulse in both AC and DC modes and it comes with a wide range of frequency controls (PPS).

This allows the plasma cutter to deliver professional-level performance while still being budget-friendly, and it greatly outperforms plasma cutters that are within the same price range, making it a great choice for both those that have just started out welding, as well as professionals.

You can go ahead and check the AlphaTIG 203XI’s Amazon page, since they have frequent sales, and it would be a shame to miss out on the chance to pay less for a plasma cutter that is already very affordable.

Specs:

- Duty Cycle:60%

- Size: 20 x 19 x 11″

- Weight:47.4 lbs

- Input Power:110/220V 60Hz

- Output Current:60A

Pros:

- Capable of handling most welding applications

- Powerful 200 amp AC/DC TIG welder

- Includes MMA welding function

- 60% duty cycle at 200 amps

- High-frequency TIG start

Cons:

- The foot pedal is not very ergonomic

5. Reboot MIG150

The last entry on our list is the Reboot MIG150, another reliable plasma cutting tool that is a bit different from the previous entry because it comes with both gasless (flux core wire) and gas-based (solid wire) welding capabilities.

However, this plasma cutter is perfectly capable of supporting 2lbs .030-inch or .040-inch wires that can weld carbon steel, stainless steel and mild steel plates that are as thick as 0.30-inches.

Power aside, the MIG150 is the smallest plasma cutter from Reboot, weighing in as just 22.7 lbs, so carrying around will be extremely easy, and if you do decide to get this plasma cutter, know that you will get more in the package other than the device itself.

For example, you will get one dual Mig150, an earth clamp, one electrode holder, one welding torch, 2lbs of flux-cored wire, one welding hose, and a 20mm conversion line.

The biggest selling point of this plasma cutter is the extremely low price (it’s so low that many users justifiably doubt its quality) but our tests show that it did a very good job considering how much was paid for it.

In fact, go ahead and check the product out yourself and see how affordable it is.

Specs:

- Duty Cycle: 85 %

- Dimensions: 9.65 x 5.91 x 7.09 inches

- Weight: 22.7 lbs

- Input Power: 220V 60Hz

- Output Current:30-160 A

Pros:

- The English manual is well made and easy to understand

- The package contains plenty of accessories to get you started

- The gun is well made with a sturdy build and a cord that is of sufficient length.

Cons:

- Doesn’t come with a large spool adapter

What Is Plasma Cutting?

If you’re looking for a budget-friendly plasma cutter, chances are that this may well be your very first plasma cutter (who would want to invest a lot in a machine they have little experience with?).

As such, we would like to start off by showcasing what exactly is plasma cutting, so that you can understand by these machines can be so useful, and why they tend to be so expensive in general.

Plasma cutting is the process of creating a jet of hot plasma as a means to cut through electrically conductive materials (usually metals).

This process is usually used when dealing with electrically conductive materials like:

- Stainless steel

- Aluminum

- Copper

- Brass

- Steel, etc

Plasma cutting is usually used in fabrication shops, repairing and restoration vehicles, construction work, and other activities heavily industrialized activities where enormous quantities of metal may be involved.

However, since you don’t actually need any certification to use a plasma cutter (just protective equipment and common sense), the average user can take up this activity in their day to day life, as it can be incredibly useful around the house.

Because of this, if you like repairing and restoring things such as your own house or car, knowing how to plasma cut can be incredibly useful.

Besides, while the initial investment may be a bit large (unless you choose to follow the entries in this article, of course), operating a plasma cutter, as well as the consumables, can be very cost-effective, so those of you that will be using it consistently will see a return-on-investment in no time at all.

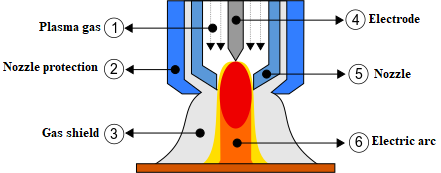

How Does Plasma Cutting Work?

The basic principle behind plasma cutting is creating a beam of superheated electrically ionized gas (a.k.a. plasma). The plasma is generated by the plasma cutter, and it is generated through the material that you are working with.

This process forms a complete electrical circuit back to the plasma cutter via a grounding clamp.

The gas itself is compressed and blown out through a nozzle aimed at the material that you will be cutting. Speaking of gas, the one that is used in plasma cutting can be one of many, with some gases being optimized for cutting certain materials:

- Oxygen

- Air

- Inert, etc

An electrical arc is then formed within the gas between an electrode and the working material itself (that’s why the process only works on electrically conductive materials). The electrical arc’s purpose is to ionize some of the gas, which finally leads to the creation of the electrically conductive channel of plasma.

This jet of superheated plasma not only creates enough heat to melt your target material but the pressure from the high-velocity plasma and compressed gas blow the hot molten metal away, which helps with separating (cutting) the two melted pieces.

Besides, because the blown gas creates a very hot and very localized cutting cone, plasma cutting is ideal when you need to cut sheet metal in curved or angled shapes.

Here’s how plasma cutting works step-by-step:

- An initial spark ionizes the gas inside the torch head.

- This makes the gas to be conductive which in turn allows the initial arc to form.

- The initial arc then forms inside the torch head.

- The plasma’s current then flows from the electrode to the nozzle within the torch head.

- The initial arc burns up the nozzle during this phase.

- The plasma is then blown out of the nozzle towards the working material due to the compressed gas.

- This provides a current path from the electrode to the working material.

- When the plasma cutter’s control system senses current flowing between the electrode and the working material, it will cut the electrical connection to the nozzle.

- Current then travels from the electrode to the working material allowing the arc to form inside the nozzle.

- You can then start cutting without fearing that you will burn up the nozzle.

Note: Because of how this process works, the life of the nozzle is not dictated by the cutting time, but rather by the number of arc starts, therefore rendering nozzles consumables.

What Consumables Are Needed in Plasma Cutters

Speaking of consumables, before you go ahead and buy yourself a plasma cutter, you need to remember that other investments will be involved as well, not just the plasma cutter itself.

You see, in order to obtain an efficient and safe cut, there are certain consumables that you will need to use on a regular basis, so make sure that you have plenty before starting a cutting job.

Torch Body

The torch body is to be the working end of the plasma cutting system, serving the following purposes:

- It’s the source of pre-flow, plasma gas, and shield gas for the other consumables

- This is the piece that delivers the cutting current to the electrode

- Fixates the other consumable parts in perfect alignment

Electrode

The electrode is probably the most noticeable consumable in a plasma cutter, as it is probably known even by people that have never even used a plasma cutter before themselves.

The main function of the electrode is to provide power to the plasma arc, acting as both the starting point and electrical contact point of the plasma arc. Typical electrodes are usually made of tungsten or hafnium, due to the material’s high melting point.

Nozzle

Due to the nozzle’s perfectly round orifice and the sharp inner and outer edges, it allows the plasma to flow in a way that will create cuts that are both sharp and precise.

As mentioned earlier, the nozzle’s lifespan is dictated by the number of arc starts, but it can also be affected by incompatibilities between the other consumables since they need to be a perfect match.

Note: In order to ensure the best cut quality, we recommend that every time you change the nozzle, you change the electrode as well.

Swirl Ring

The purpose of the swirl ring is to control the swirling movements of the plasma as it is blown out of the nozzle around the electrode, and acts as a key component that prevents the plasma to burn the nozzle after the initial arc start.

One way to increase the lifespan of not only the swirl ring but also the nozzle and the electrode is to make sure that the swirl holes are not clogged with dirt or other debris.

Note: With proper maintenance, swirl rings can even last through several electrode and nozzle changes.

Shield

Just as its name leads you to believe, the shield’s main purpose is to protect the other components of the plasma cutter, along with other features:

- Increases cutting quality and allows for faster cutting speeds

- It protects the nozzle from molten splatter material

- It enables drag-cutting when using a hand torch

- It allows the nozzle to keep cool

What to Look for in a Plasma Cutter

Now that you know how plasma cutting works and what materials you will have to use and replace over time, it’s time to talk about the actual specs that you will need to focus on when looking to buy a brand-new plasma cutter.

Duty Cycle

A plasma cutter’s duty cycle should be the first thing that you look at when browsing to buy on, as it is the criteria that has the most impact on how the cutter will perform.

When talking about plasma cutters, the duty cycle is its ability to work at a specified capacity for a set amount of time, and it is usually dictated by the device’s amperage rating and is usually displayed as a fraction or as a percentage.

The duty cycle in turn is directly correlated with the plasma cutter’s ability to cut sheet metal of a specific thickness, with higher duty cycle ratios allowing you to cut through thicker and thicker materials.

The process of plasma cutting can be used on materials of a variety of thicknesses, although the exact limit is dictated by the plasma cutter’s power. For example, small handheld plasma cutters can cut a 38 mm (1.5 in) thick steel plate, while the much stronger computer-controlled torches can cut steel up to 150 mm (6 in) thick.

Plasma cutters with a lower duty cycle provide optimal performance for a limited duration, after which performance levels start to drop, meaning that the cutting will take longer to finish.

For those of you that are mostly interested in heavy-duty projects, look for devices that have a listed duty cycle of around 50% – 60%, as they will be more than enough.

For the purpose of this article, the average plasma cutters you should look for should be able to handle cuts that are at least a quarter-inch thick. Sure enough, they can be used on much thicker materials, but the precision of the cut will be compromised.

Electrical Input and Output

Since plasma cutters can be dangerous, it’s wise that you only use and store them in designated spaces, usually crafting rooms. However, before you go ahead and buy the plasma cutter itself, make sure that your room is equipped with proper power outlets that will meet its needs (110V or 220V outlets will suffice).

More so, make sure that the circuit breakers in your crafting room can withstand the amperage of both the plasma cutters and the compressors.

Cutting Thickness

While it is true that you won’t always be cutting the same sheets of metal over and over, you probably know already what types of materials you will be working with most of the time.

That being said, the next criteria you should take into consideration when buying a new plasma cutter is the cutting thickness, so if you only ever plan on cutting through very thin materials, you can go ahead and go for the least powerful ones on the market.

Weight

If you’re a professional that does metal cutting for a living, a part of your job will involve travelling between work sites, which in turn means that you’ll be carrying the plasma cutter with you everywhere.

That being the case, compact size and reduced weight can be really helpful, so if you have no way of actually seeing the plasma torch to gauge its size and weight, pay very close attention to the product’s specs and reviews since you don’t want to buy a product that will cost you your back in just a few month’s time.

Costs

Since your main concern is how much does a plasma cutter cost, other criteria that you will need to pay attention to is the price. However, we are not talking about choosing the cheapest product around, since that would be easy, but rather the most cost-efficient product that fits your needs.

On one hand, there’s no need to pay too much on a high-performance plasma cutter if you’re only looking to do one job with it and then store it in the shed and let the dust settle on it.

On the other hand, if you plan on using the plasma cutter regularly, keep in mind that cheaper models tend to burn through the consumables a lot faster, turning your initially cheap investment into a costly one in the long run.

Best Cheap Plasma Cutters: Closing Thoughts

Now that you know what plasma cutting is, what it involves, and what you need to look for in a plasma cutter, we hope that you can make a much more informed decision when you decide to make your next big purchase.

However, keep in mind that there is no precise standard, and the choice is entirely up to you, as the best tool for the job depends entirely on what you need it for.

That being said, before you go ahead and spend money (even budget-friendly plasma cutters cost several hundred dollars), make sure you plan ahead and know exactly what kind of cuts you’re planning to make, what materials you will be using, and how thick they will be.

Besides, we recommend that you not only look at the pros of a product but also at the cons as well, especially when it comes to issues that deal with a plasma cutter’s performance.

Lastly, take into account that plasma cutters need consumables as well, so don’t go running off and buying the cheapest machine you see, since you might end up paying more in the long run.

All in all, the products that we’ve included on our list were chosen so that they met the needs of a wide variety of users, and that is why one of our entries isn’t exactly budget-friendly but showcases incredible cutting prowess.

Let us know if there’s any other plasma cutter that you think deserves a top spot on our list, we’ll review it, and then we will update the article accordingly.